The Professional Machine Shop Solution

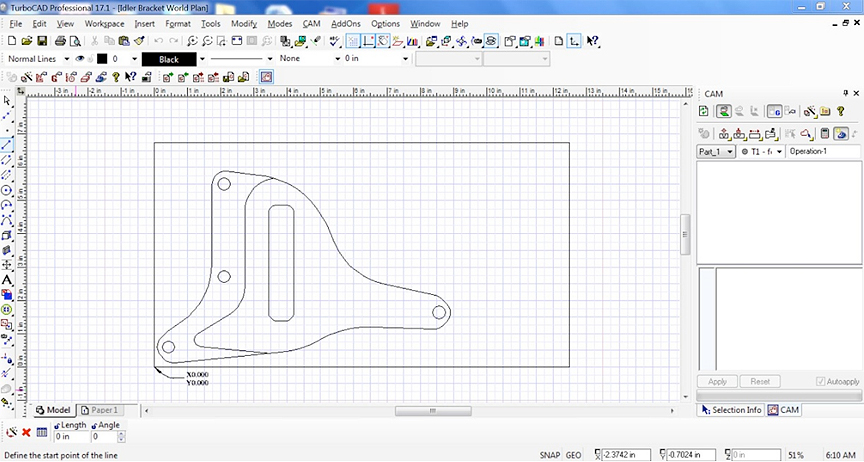

The CAM Plug-in for TurboCAD Pro is a professional solution for

2-1/2D computer aided machining (CAM).. The plug-in, in

combination with TurboCAD Pro, provides unparalleled flexibility

and productivity. Unlike typical solutions in which the design,

CAM, and post-processing are in two or even three distinct

phases; the CAM plug-in performs all phases with integrated,

non-linear associativity. That means you can make a last minute

design change and all machine setup, drill-paths, and

post-processing equivalent native g-code generation are updated

automatically to reflect those changes.

With many CAM products there are several

distinct activities:

- Import the drawing or design the

part, and clean up the drawing.

- Define the tool paths based on, for

example, a 1/4" drill bit.

- Export the design.

- Import the design into the

post-processor.

- Perform post-processing setup.

- Export g-codes.

Any change to the drawing, the paths, or the tool size, for

example, and many applications force you to go back to step 1.

Not the CAM Plug-in for TurboCAD Pro!

The CAM Plug-in for TurboCAD Pro performs steps 1-6 in an

associative manner so that a change to bit size, or a design

change to add a peck-drilled pocket can be performed at any time

and all other steps including the g-code are automatically

updated. Work on the project in the order that makes sense to

you. Design changes, revisions, secondary milling for precise

finishing can all be made quickly and efficiently.

Productivity is ennhanced further with design simulation and 3D

rendered views of the completed part. The plug-in offers

step-by-step simulation in 3D wireframe, hidden line, or

rendered mode. Models may be viewed in completed rendered mode

or exported as STL solid models. CNC programmers will see

significant time savings, and material savings by spotting and

correcting errors before the DNC downloads g-codes to the

controller.

Using the TurboCAD Pro constraints in the design means that an

entire part may be automatically modified by changing a single

variable dimension. With the single value being entered, all

corresponding drill paths and g-codes are updated. This is a

simple way to define entire part families.

Why Choose CAM Plug-in for TurboCAD?

- Superior productivity gains from an

integrated end-to-end solution — there is no external

post-processing required; the part tree format allows for

tight integration of changes with all steps in a non-linear

fashion.

- Extremely efficient tool management

— a highly sophisticated path-finding algorithm optimizes

tool paths as you work; this produces the best machining and

the most efficient use of the tool, while reducing both

design time and machining time.

- Broad drawing compatibility —

integrated with TurboCAD Pro which supports 26 file formats

for import, including DWG, DXF, IGES, and STL.

- Provide a complete view of the

resulting design — export a complete machcined model in STL

format or a high quality rendering.

- Improved quality and accuracy — up

to 10 digits of precision is supported and measurement can

be singularly or globally changed from imperial to metric,

easily exceeding the highest level of accuracy supported by

most controllers.

TurboCAD

PRO için CAM desteği: 2.5 Boyutlu G-kodu

çıktısı

TurboCAD

PRO için CAM desteği: 2.5 Boyutlu G-kodu

çıktısı TurboCAD

PRO için CAM desteği: 2.5 Boyutlu G-kodu

çıktısı

TurboCAD

PRO için CAM desteği: 2.5 Boyutlu G-kodu

çıktısı